Zinc Sulfide is a highly purified additive. It can be used to Engineering Plastics, Coatings, Friction Materials, etc.

| Product Grade | Contents (%) |

| LS-WJ97 | ≥97 |

XINDA LS-WJ97 is a Zinc Sulfide based high purity functional white pigment. It is typically used in following applications.

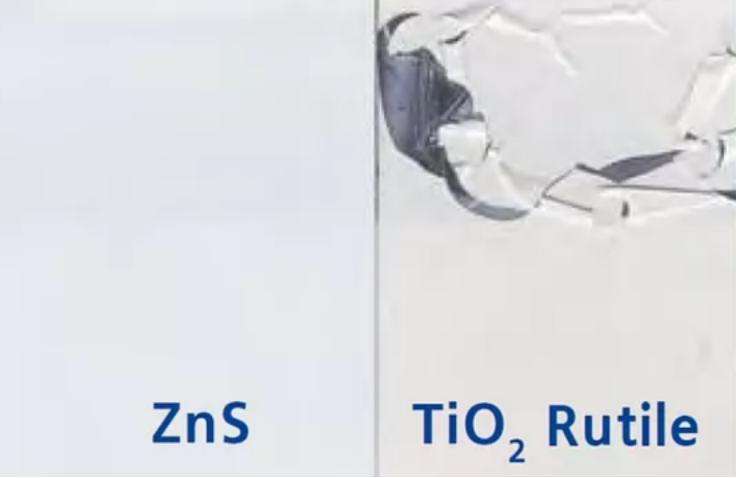

- Low Abrasiveness: LS-WJ97 has lower Mohs hardness than TiO2. So it can be used in all glass-fiber-reinforced plastics (GRPs) which require good tensile strength and other mechanical properties. With lubricating properties, it can protect machines and moulds from abrasion.

- Excellent Processing Performance: LS-WJ97 can be used as lubricant to avoid the elastomer plastic becoming brittle. It also has good dispersion and high temperature stability, which can promote the processing of high-performance plastics and improve the production efficiency.

- Excellent Optical Performance: LS-WJ97 is a unique white pigment that can be used together with optical brighteners to make brighter whiteness. Unlike TiO2, it can also prevent metal ions from entering the polymer. Therefore, it can improve the weather resistance of plastic.

Example of Application

- Glass Fiber Reinforced Plastic

- Mixing with TiO2, PA66 glass fiber reinforced will significantly reduce its mechanical properties. However, using Zinc Sulfide LS-WJ97 to replace TiO2, the mechanical properties are well retained.

- Prevent Cracking: LS-WJ97 has high thermal conductivity and keeps the coating at appropriate temperature to avoid cracks.

- UV-Curing Performance: Traditional white pigments will prevent UV light from entering the coating’s inside layer. Therefore, traditional white or colorful coating can not use UV curing technique. But LS-WJ97 allows more ultraviolet light enter into the coating interior, and triggers cross linking reaction of the inside photoinitiator. It can also reduce dosage of other additives so as to reduce the cost.

- Convenience in Adjustment: Low binder demand allows formulators to adjust the viscosity of the coating.

- Prevent Cracking: LS-WJ97 has high thermal conductivity and keeps the coating at appropriate temperature to avoid cracks.

Example of Application

- UV Curing Paint

Compared to TiO2, the end of the light absorption spectrum is greatly shifted into the ultraviolet region. With the efficient activation of the photoinitiator, the curing of the thicker white UV coating is faster and more complete.

The Zinc Sulfide by XINDA manufactured improve the operation of brake pads and clutch facings. Zinc Sulfide is a relatively new material in the friction industry. Compared with other metal sulfides, the product's effect is mainly reflected in the high-temperature high-speed segment, which can significantly improve the friction coefficient of the brake pad in the first recession and the high-temperature high-speed segment. Especially, the effect is the best at the extreme end temperature, so that the formulation has better braking performance.

* We have two different kinds of packaging bags. You could choose L01 or L02.

L01: Xinda information is included.

L02: Xinda information is not included.

* We have EU REACH registration certificate, REACH certificate issued by SGS, ROHS certificate issued by SGS and ISO certificate, etc.

If you need any further information, please don't hesitate to contact us!

* Contact information:

Name: Lillian Xie

E-mail: lillian@xindatech.com.cn

WhatsApp: +8619106644266